Barcodes vs RFID

Tracking Technologies for the Oil, Gas and Mining industry.

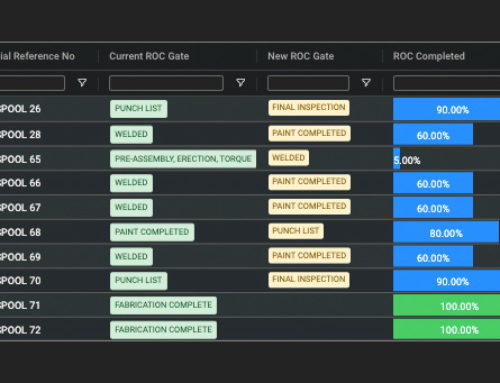

Want to get a better handle on tracking your tools, plant and equipment, materials, PPE, etc? Not entirely sure which tracking technology to use? Let us shed some light on the differences and take a closer look at Barcodes and RFID.

Barcode Tracking

Barcodes were created to print numbers so that they could be read accurately at high speeds by scanners. They consist of printed elements that represent a combination of characters. A barcode scanner or smartphone uses optical signals to scan the elements and translate them into the unique code.

There are many types of barcodes that are categorised into one-dimensional (1D) or two-dimensional (2D) designs.

1D Codes

2D Codes

RFID Tracking

Radio Frequency Identification (RFID) systems use radio signals for the identification of unique objects. An RFID tag contains a chip that is built to store roughly 16 Kbit of information.

RFID readers automatically detect the presence of RFID tags within an approximate 30-metre radius and update their status on a system. The range may vary depending on the types of tags, readers and the influence of surrounding environmental factors. RFID does not require line of sight operation and is ideal for tracking the movement of tools and personnel that are constantly moving in and out of a location.

RFID tracking technology is available in two distinct configurations: passive and active RFID.

Passive RFID

Active RFID

The table below summarises the applicability of Barcodes and RFID tracking technologies.

| BARCODES | RFID | |

|---|---|---|

| COST | Cost of barcodes range from approximately AUD 0.30 to AUD 2 per barcode. Optical scanners or smartphones can be used depending on requirements. Cost of scanners range from approximately AUD 100 for basic barcode scanners to AUD 3,000 for intrinsically safe scanners. |

Cost of tags range from approximately AUD 0.15 to AUD 30 depending on requirements. Cost of readers range from approximately AUD 1,500 to AUD 20,000 depending on requirements and feature set. |

| DISTANCE | Line of sight: 0 - 0.3 metres. | Passive: 0 – 6 metres. Active: 0 - 30 metres. *may vary according to usage. |

| POWER REQUIREMENTS | Only for the scanner. | Passive: Only for the RFID reader. Active: Requires battery power. |

| READ RATE | One barcode at a time. | Detects and reads multiple tags within a range at once. |

| SCANNING | Directional (often manual). | Passive: Manual. Active: Automated. |

| SIGNAL TRANSMISSION | Optical signals. | Radio waves. |

| DATA | Up to 25 alpha-numeric characters. Information is static. |

Up to 16 Kbit of information. Information can be changed. |

| BEST USED FOR | Tracking PPE, assets and materials. | Passive: Tracking personnel or small tools. Active: High value assets. |

Like what you have read so far?

For further information, please have a look at our Materials Tracking solution.

Want to hear more about it? We’re happy to schedule a chat, a demo or send you some additional information.