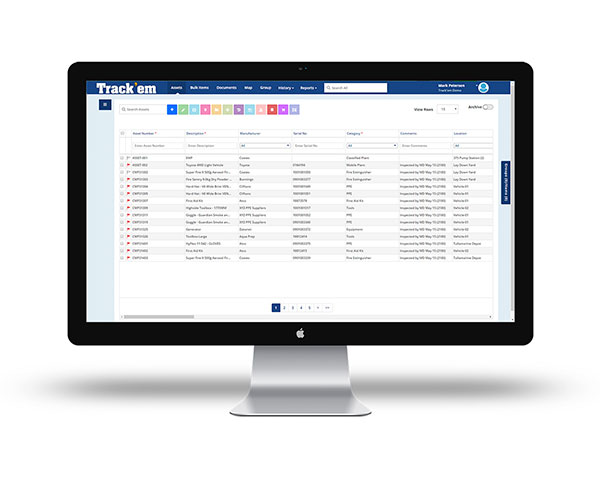

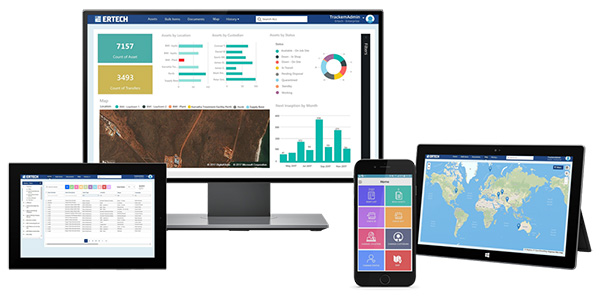

Asset Tracking and Optimisation

Plant and Equipment Tracking

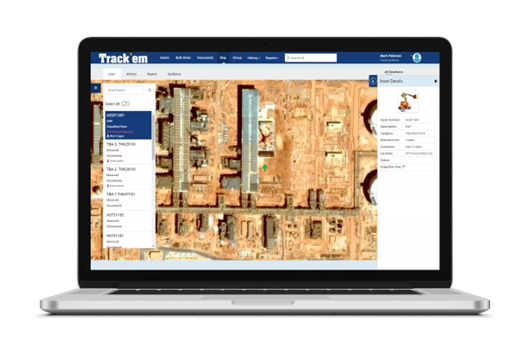

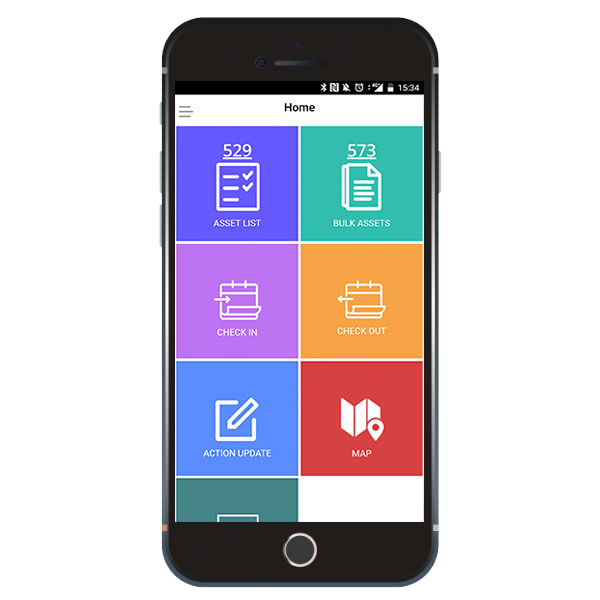

Imagine if you’d always know the location and status of your Plant and Equipment, Tools and PPE. With the information in the palm of your hand.

Maintenance, capital inspections & pre-starts finally feel organised.

Simplify safety and compliance with mobile forms, notifications and dashboards. Easy reporting tools give you control over processes.

Losing things sucks. Getting blamed for something lost by

someone else is just plain insulting.

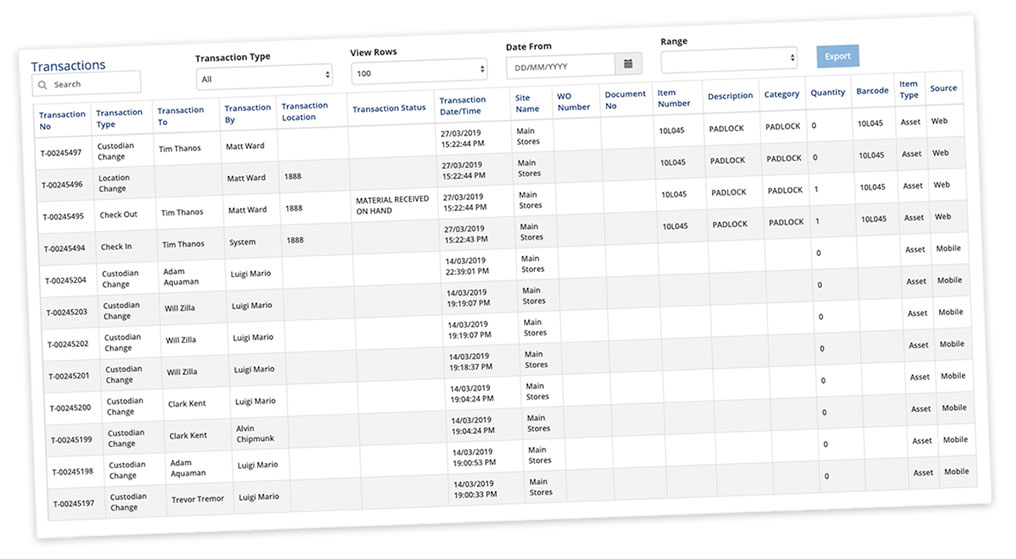

Keep track of expensive, owned or leased plant and equipment. Take control and be confident about the status, location and custodian of your assets on site and off site.

Get your rotable spares organised and under control.

Maintain visibility, lower costs, reduce administration overhead and avoid waste. Keep your warehouse, maintenance and refurbishment partners on the same page with a single view of the status and location of rotable spares.

The advantages of Track’em are the time saved, the security of knowing that the product works and that you have a full handle of day to day material – ‘it saves time and money’.

Neil Tregae, Fortescue Metals Group