Rules of Credit

Progress follows a plan

Being able to measure progress is critical for any organisation involved in large and complex construction or maintenance projects. Determining the amount of progress made, however, is reliant on the reporting on completion of the underlying project tasks. The more accurate and real-time this reporting is, the better your progress reports will be. In turn, this allows you to make informed decisions to keep the project on track.

Measuring completion

If all the steps required to complete an activity would take exactly the same amount of time and money, it would be fairly easy to determine the progress. By looking at the percentage complete of the individual steps, you can derive the total completion of the project. In other words, if you’ve completed 40% of the steps or spent 40% of the money, you’ve completed 40% of your project.

Unfortunately, this utopian project scenario hardly applies to real life as the steps are rarely equally weighted. What if the first few steps cost significantly more than the last few steps? Or what if certain economies of scale come about for repetitive work?

A simple example

Say we need to create a structure and that the core frame of this structure consists of steel. While we require various shapes and sizes of steel, every piece follows the exact same installation process. The steps in this process, however, are not all of equal duration. Some simply take longer than others.

To install a steel part, we need to go through the following stages:

- Prepare the installation area

- Pre-assemble steel part

- Installation/erection of steelwork

- Alignment, bolting and torquing

- Walkdown, inspection and works to go

- Final signoff

As these steps all take a different amount of time to complete, it would be unrealistic to say that once we’ve finished step 3 for a particular piece of steel, we’ve finished 50% of its installation.

Rules of Credit

This is where rules of credit (ROC) come in. The term ‘rules of credit’ consists of two parts, both of which are equally important:

- Rules: This is a set of agreed terms or sequential tasks that something must go through before it is completed.

- Credit: This refers to the weighting given to each of the rules (tasks) in terms of percentage complete.

Where are rules of credit applied?

In the construction, mining and oil and gas industries, rules of credit are commonly used to monitor progress for the installation of components. They are also commonly used by fabricators to measure fabrication completion of parts. Procurement departments rely on rules of credit to hold contractors accountable and issue payments for the work completed.

Rules of credit help determine total percentage complete by adding a weighting to the individual tasks.

Weighted steps

By having a ‘rules’ and a ‘credit’ component, the rules of credit allow us to start doing weighted calculations on our total percentage complete. The purpose of the rules of credit is to take away ambiguity as to what the percentage complete is. It is something that all involved stakeholders agree on, and therefore, often used in contractual and payment term arrangements.

Let’s take a look at our structural steel example again and apply weighting to each of the rules by setting a percentage complete. This percentage complete is an indication of the total percentage complete of the installation of a steel part after that task has been finalised.

- Prepare the installation area – 5%

- Pre-assemble steel part – 35%

- Installation/erection of steelwork – 75%

- Alignment, bolting and torquing – 85%

- Walkdown, inspection and works to go – 95%

- Final signoff – 100%

The total of all the steps must always add up to 100%, indicating that this steel part has been completely installed. In the example above, we can now see that if we’ve finished step 3, we’ve actually finished 75% of the total installation.

How are rules of credit managed in Track’em?

Track’em Materials facilitates the management of rules of credit by applying them to materials on various levels. Different stages or stakeholders involved with the project may have different rules of credit for the same materials. As materials progress through the various supply chain stages, the total completion of the steps can add up to 100% for a specific part of the supply chain process. This is best explained by an example.

Say our materials go through the following supply chain stages:

We want to apply rules of credit to the fabricator stage and the work front stage to measure progress, but the rules of credit for each of these stages are very different.

In Track’em, we can implement this by creating two separate rules of credit templates (ROC-templates); one for the fabrication stage, and one for the work front installation stage. Once we’ve created the ROC templates, they can be assigned to (sub)categories of materials. As such, every (sub)category can have its own rules of credit within each supply chain stage.

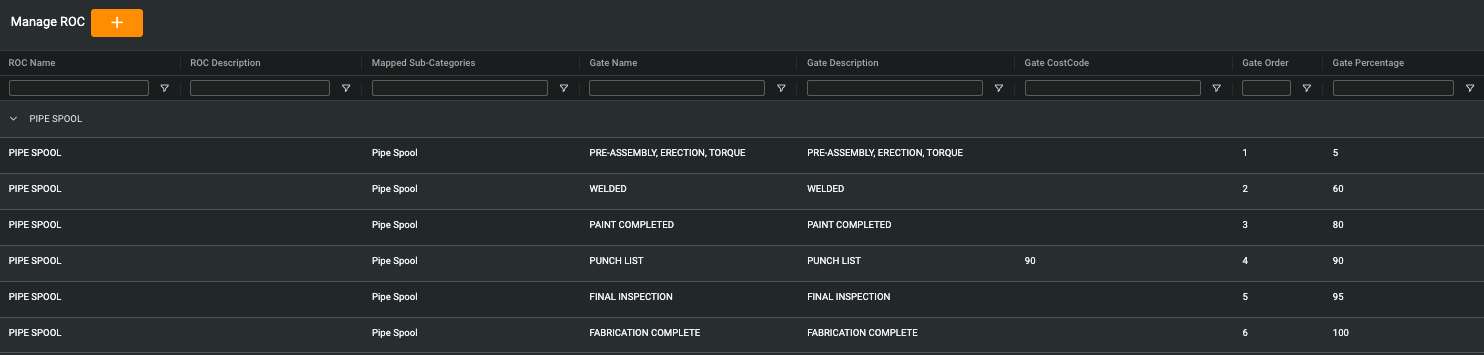

For example, for Pipe Spools, we may have the following rules of credit setup at the fabrication stage.

Defined Rules of Credit for Pipe Spools at the Fabrication Stage – Click image to enlarge.

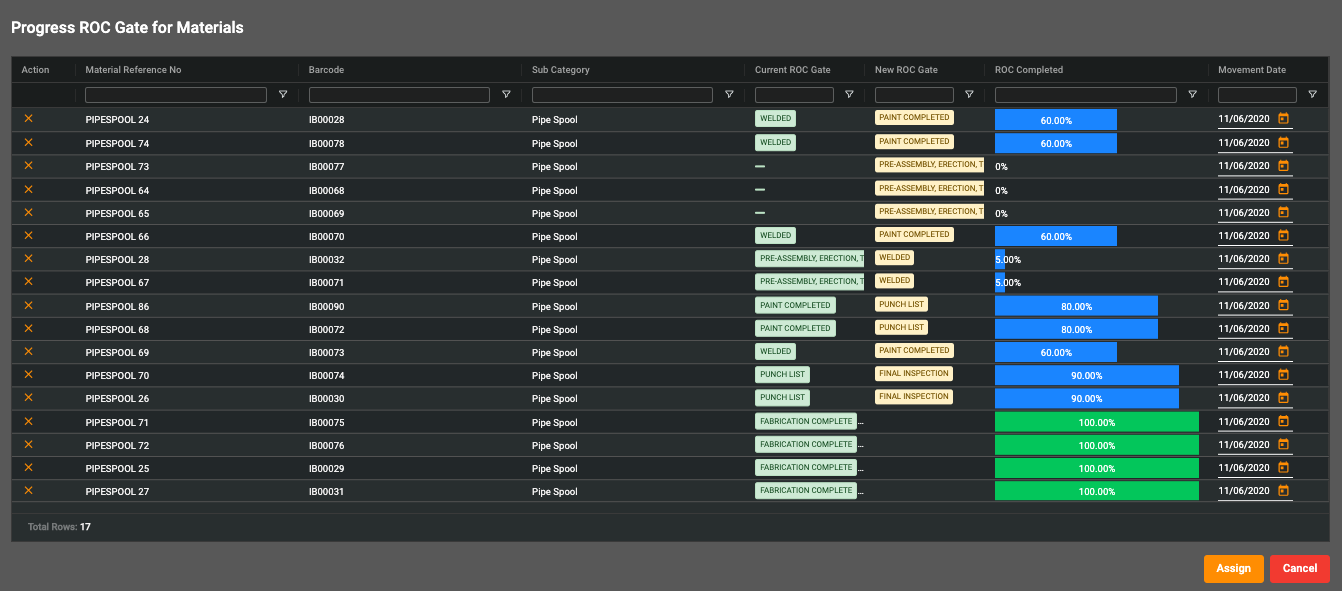

When end-users are looking at the pipe spools in Track’em Materials, they’ll quickly be able to see what ROC stage they’re in and progress them to the next ROC gate.

Pipe Spools Rules of Credit Status at the Fabrication Stage – Click image to enlarge.

Once the relevant pipe spools are at 100%, the fabricator can move them through to the next stage of the supply chain, which would be transport in our example.

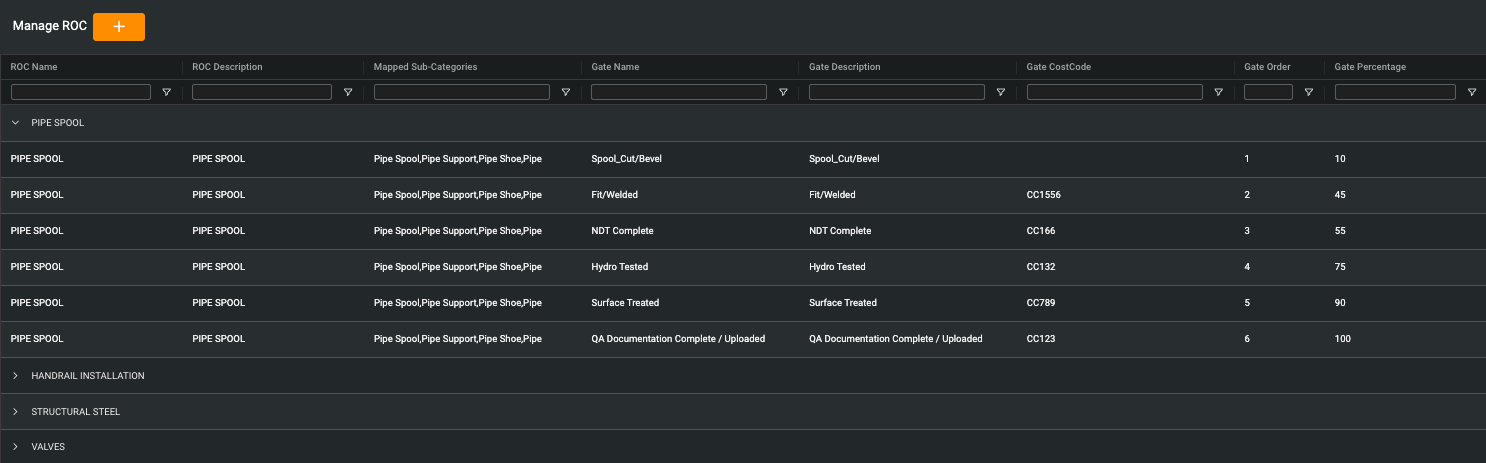

Now let’s skip ahead in the supply chain to the last stage: work front installation. When all the pipe spools have been issued to the site, we now want to apply a different ROC-template that is specific for the task to be taken on-site. For our pipe spools, a new ROC-template is required specific to this stage of the project, see the example below.

Defined Rules of Credit for Pipe Spools at the Work Front Installation Stage – Click image to enlarge.

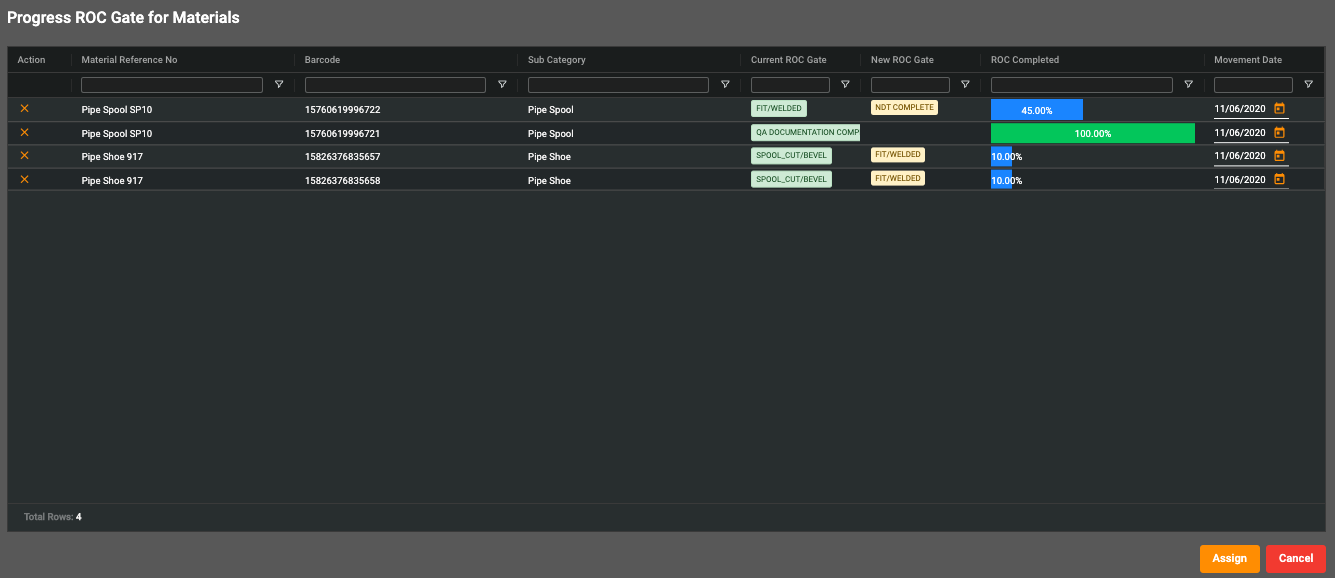

And similarly, the materials can be transitioned through the ROC gates for the stages on-site.

Pipe Spools Rules of Credit Status at the Work Front Installation stage – Click image to enlarge.

Start Managing Rules of Credit

Managing Rules of Credit is an important part of materials control. Track’em enables you to manage ROC for your materials and track progress based on weighted and agreed rules. Tracking Materials with Track’em gives you full visibility and control of your materials across the supply chain enabling you to make decisions based on real-time information from the field.

If you have any questions about ROC or how Track’em can help with your material tracking challenges. Don’t hesitate to contact us. We’re here to help.