Materials Tracking Software

NEW RELEASE

We’re proud to announce a new release of our Materials Tracking software. This major release includes many new and improved features – based on years of field experience and customer feedback – that allow users to manage their construction materials across the supply chain even better. Besides the impressive catalogue of functionalities, the new release also includes a refreshed and more intuitive user interface.

What does our Materials Tracking Software do?

Our Materials Tracking solution is designed to track construction materials across every step of the supply chain. The secure SaaS environment digitises processes, consolidates information and gets you out of paperwork and spreadsheets through intuitive apps. It does this by integrating with serial identification through barcodes and QR codes, as well as IoT technology (GPS, RFID, Bluetooth, etc.) to give you real-time data of any movements, change of hands, and usage.

The goal?

Making sure the right materials are available on-site, on-time in the right quantity and quality; preventing costly delays caused by unavailable parts.

Who is it for?

Track’em Materials offers a single platform connecting all stakeholders and departments involved with handling and processing construction materials. Through role-based permission levels, any stakeholder involved with the production, delivery and installation of materials has access to information relevant to them.

Typically, roles using the system are:

On what devices?

The materials tracking software is available as a web app on a (desktop) browser or through our mobile apps. Any device running iOS or Android, including smartphones, tablets, smart scanners and intrinsically safe devices, can be used to find, scan, locate update and inspect materials.

So what’s new?

Besides having completely rebuilt the product from scratch to include the latest and greatest cloud technology stack, we’ve made significant changes in the design and enriched the functionality to support more materials handling operations.

A new skin

The first thing you’ll notice is the change of the look and feel of the entire application. Both the desktop version as well as the mobile apps have been given a more intuitive and modern design. Structural changes in the user interface have enriched the functionality while making it possible for users to do more with fewer clicks. Additionally, the system is more aligned with the rest of the Track’em software suite. As such, users of our Asset Tracking software will immediately feel at home in the new Materials platform.

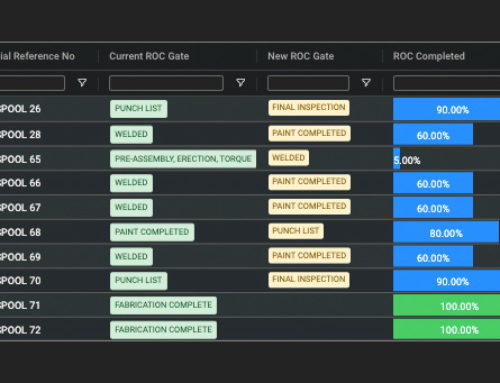

Speed

Our tech team has spent plenty of time on backend optimisation. As a result, the product is faster than a speeding nail from a nailgun and can handle tens of thousands of line items with ease. The main grid — which is the heart of the application — holds an immense amount of material information while still being a breeze to work with. It provides a clear overview of your materials’ current location, status and custodian. Basically — everything you want to know about your materials, in one overview.

"We have completely rebuilt our Materials Tracking Solution taking on-board years of best practices from tracking millions of items across successful roll-outs in the field.”

Kashif Saleem

Founder and CEO, Track’em

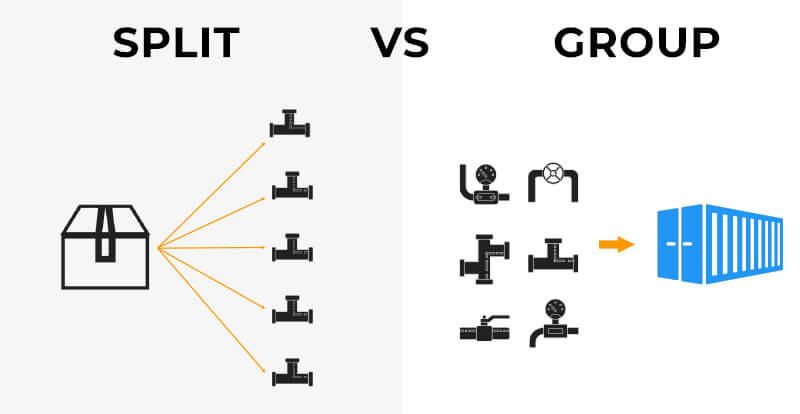

Splitting and Grouping Materials

While it was always possible to group (and ungroup) materials and track them collectively as one entity, it is now also possible to split items. In the real world, ‘splitting’ items happens daily and is something every material controller requires.

Let’s take an example: Materials often arrive in packages or batches. Each of these packages is (tracked as) a single line item or Purchase Order (PO) number. Upon arrival, the contents of a package need to be split into separate (line) items that get dispersed to different sites, and therefore, need to be tracked on an individual basis. However, for audit and Quality Assurance (QA) purposes, it is important to be able to trace back the origin and details of each split item to its source (i.e. PO number, heat number, country of origin, etc). Track’em Materials facilitates this by maintaining a full record of this information, no matter how often an item has been split or grouped.

Manage Bulk Fabrication Materials separately

Track’em Materials now enables you to handle bulk fabrication items as a distinct group. This makes it possible to track the consumption of bulk materials and allocate them to components for fabrication.

For quality assurance purposes, you’ll always be able to trace back the bulk fab components that make up fabricated parts, including their origin and the quantity that used.

Over, Short or Damaged Reporting

Did you receive something in the wrong amount? Or were materials damaged in transport? You can now lodge and delegate Over, Short or Damaged (OSD) reports digitally. The system automatically records and monitors the status of each report.

Handling Materials Transfers Requests and Lists

Within the Materials Tracking software, it is now possible to add Materials to lists. Lists are used to transfers materials from one milestone to the next. The creation of a list triggers the materials team to action materials on that list. Examples are picklists, materials transfer requests, requests for inspection, fabrication requests, etc.

Inspections

Track’em’s inspection module has been integrated as a core component of the system. This allows you to create and manage inspection forms from within the application itself. Field users can fill out the forms through the mobile app on-site as they’re doing pre-starts or maintenance work. The apps also support the attachment of photos while filling out the forms.

Attaching Documents and Photos

The new attachment file structure provides greater flexibility when it comes to storing and accessing photos, reports, manuals, certificates, documents and other important files that need to travel with materials.

Reporting on steroids

Powerful dashboards based on real-time data give you an overview of the status and usage of your materials on any level. Pivot tables and interactive drill-through graphs provide the required level of granularity to make confident decisions that drive on-time and on-budget project delivery.

"Our Materials tracking software is much more than a tracking system. It drives accountability, takes care of quality assurance and control, and gives you real-time insight into the status of your materials anywhere in the world."

Mark McIntyre

Global VP of Sales